Description

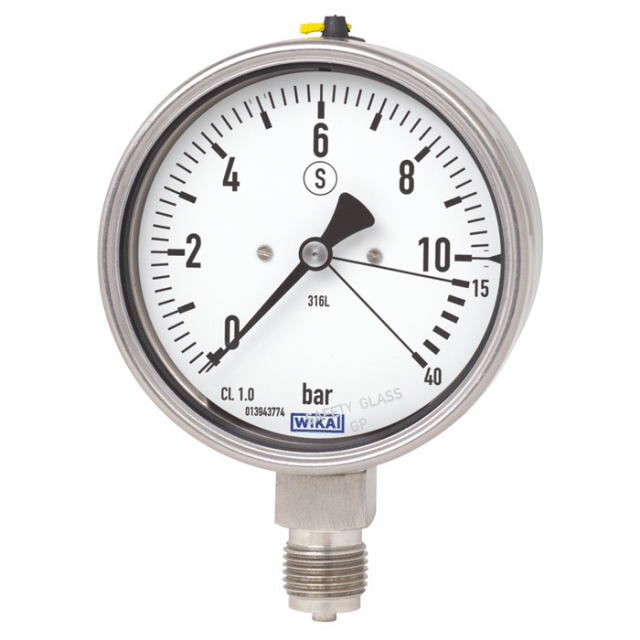

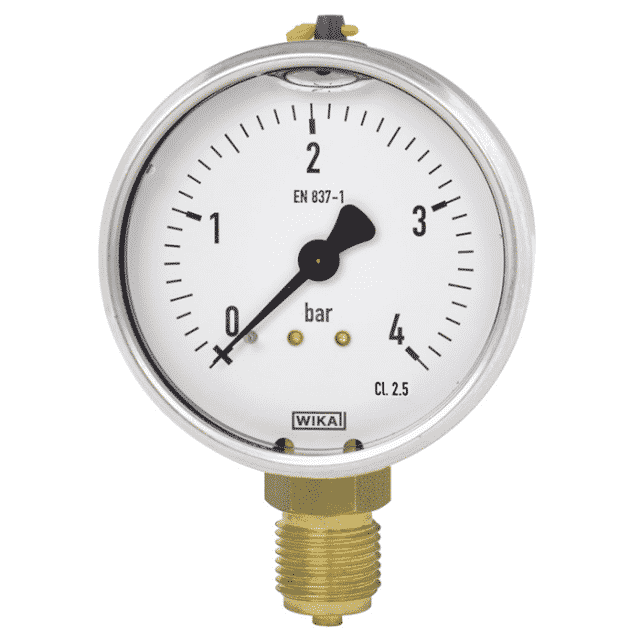

This high-quality Bourdon tube pressure gauge has been designed specifically for the display of occasional overpressure loads. The instrument can withstand up to 4 times the full scale value for short periods, without damage.

The use of high-quality stainless steel materials and the robust design are geared to applications in the chemical and process engineering industries. Thus the instrument is suitable for liquid and gaseous media, also in aggressive environments.

Measuring ranges from 0 … 0.6 to 0 … 40 bar [0 … 10 to 0 … 600 psi] are available for a wide variety of applications.

WIKA manufactures and qualifies the pressure gauge in accordance with the standards EN 837-1 and ASME B40.100. This safety version is made up of a non-splintering window, a solid baffle wall between measuring system and dial and a blow-out back. In the event of a failure, the operator is protected at the front side, as media or components can only be ejected via the back of the case.

For harsh operating conditions (e.g. vibrations), all instruments are also available with an optional liquid filling.