Description

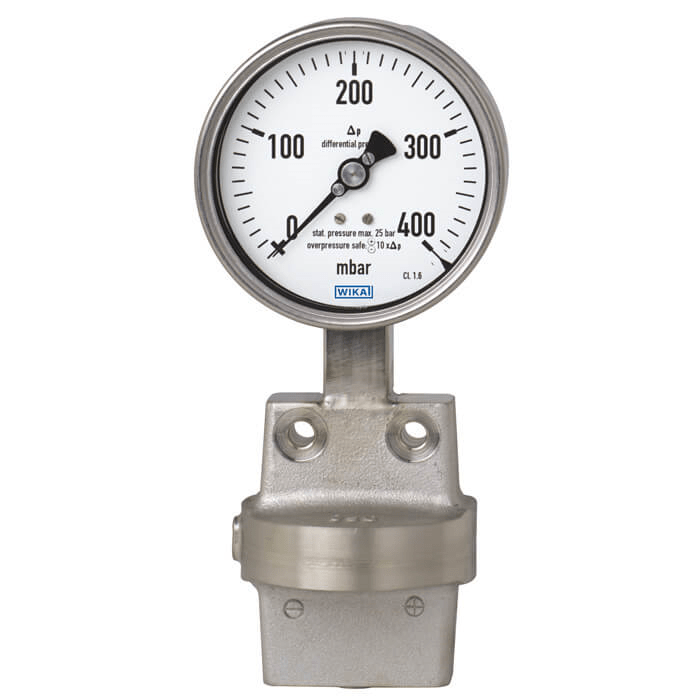

These differential pressure gauges are made of highly corrosion-resistant stainless steel and feature an all-metal media chamber to ensure long-term leak tightness (no elastomer sealing elements).

A high overload safety is achieved by the all-metal construction and the close-fitting design of the diaphragm measuring element.

The use of high-quality stainless steel materials and the robust design are geared to applications in the chemical and process engineering industries. Thus the instrument is suitable for liquid and gaseous media, also in aggressive environments.

The low-temperature version POLARgauge® allows operation with ambient temperatures down to -70 °C [-94 °F].

Cases with safety level “S3” are fitted with a non-splintering window, a solid baffle wall between measuring system and dial and a blow-out back. In the event of a failure, the operator is protected at the front side, as media or components can only be ejected via the back of the case.

Scale ranges of 0 … 16 mbar to 0 … 40 bar or 0 …10 inH2O to 0 … 600 psi ensure the measuring ranges required for a wide variety of applications.