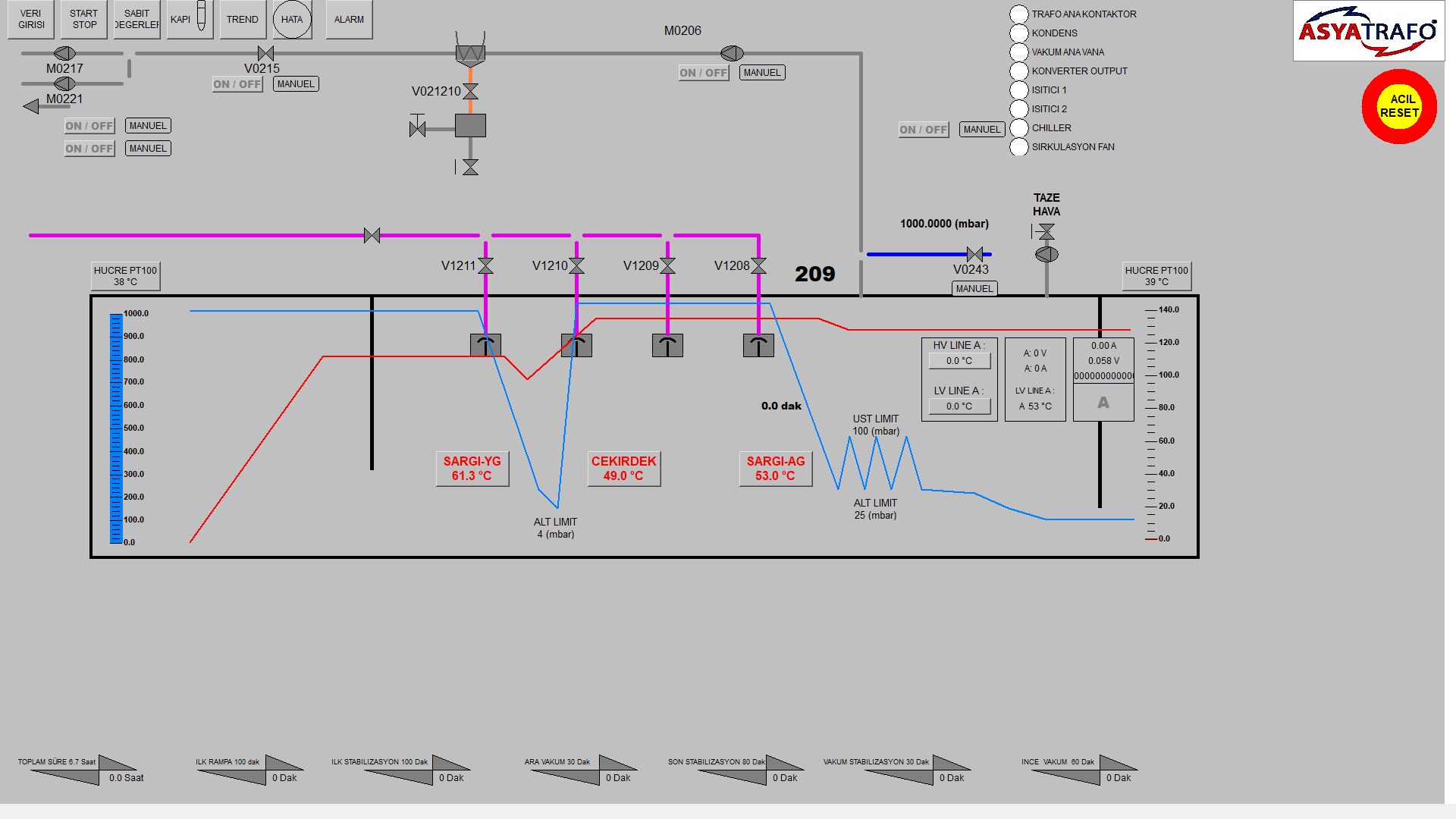

ASYA TRAFO presents new transformer drying technology known as Low Frequency Heating Equipment. This technology is used by applying a current to the windings at a low frequency (in mHz) in order to generate sufficient heat energy in distribution or power transformer active part. This operation is proceeded partially under vacuum via PLC control unit. Thus our customers can get more precise and efficient results while taking moisture away from the transformers. Our service can be either mobile or stationary according to your working conditions.

Low Frequency Heating

System Advantages

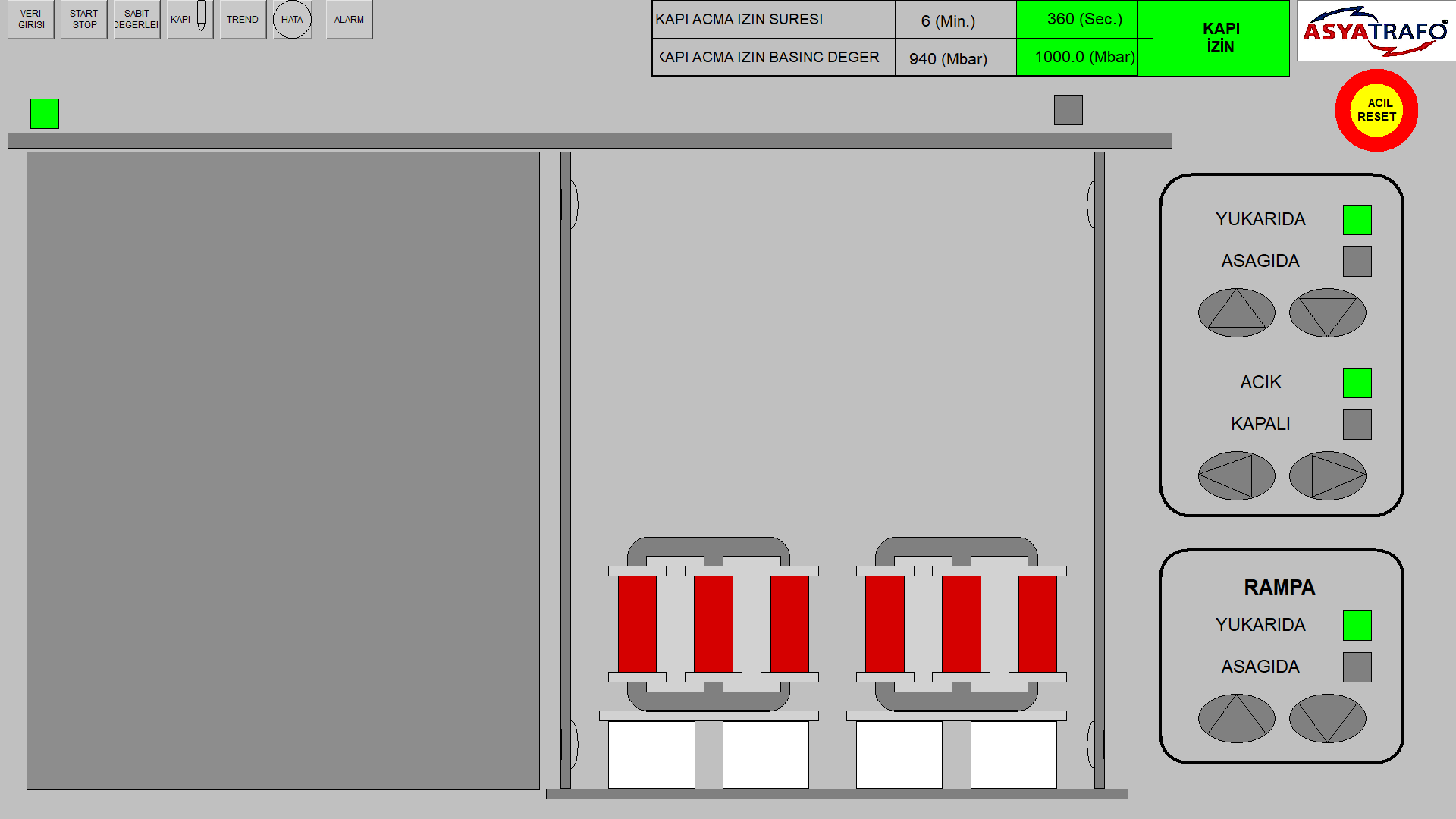

- Many transformer drying options at the same time according to system capacity and oven size,

- Minimum depolymerization – aging of insulation,

- Up to 40% lower energy consumption,

- Minimum 50% shorter drying process time,

- Higher and accurate moisture reduction.

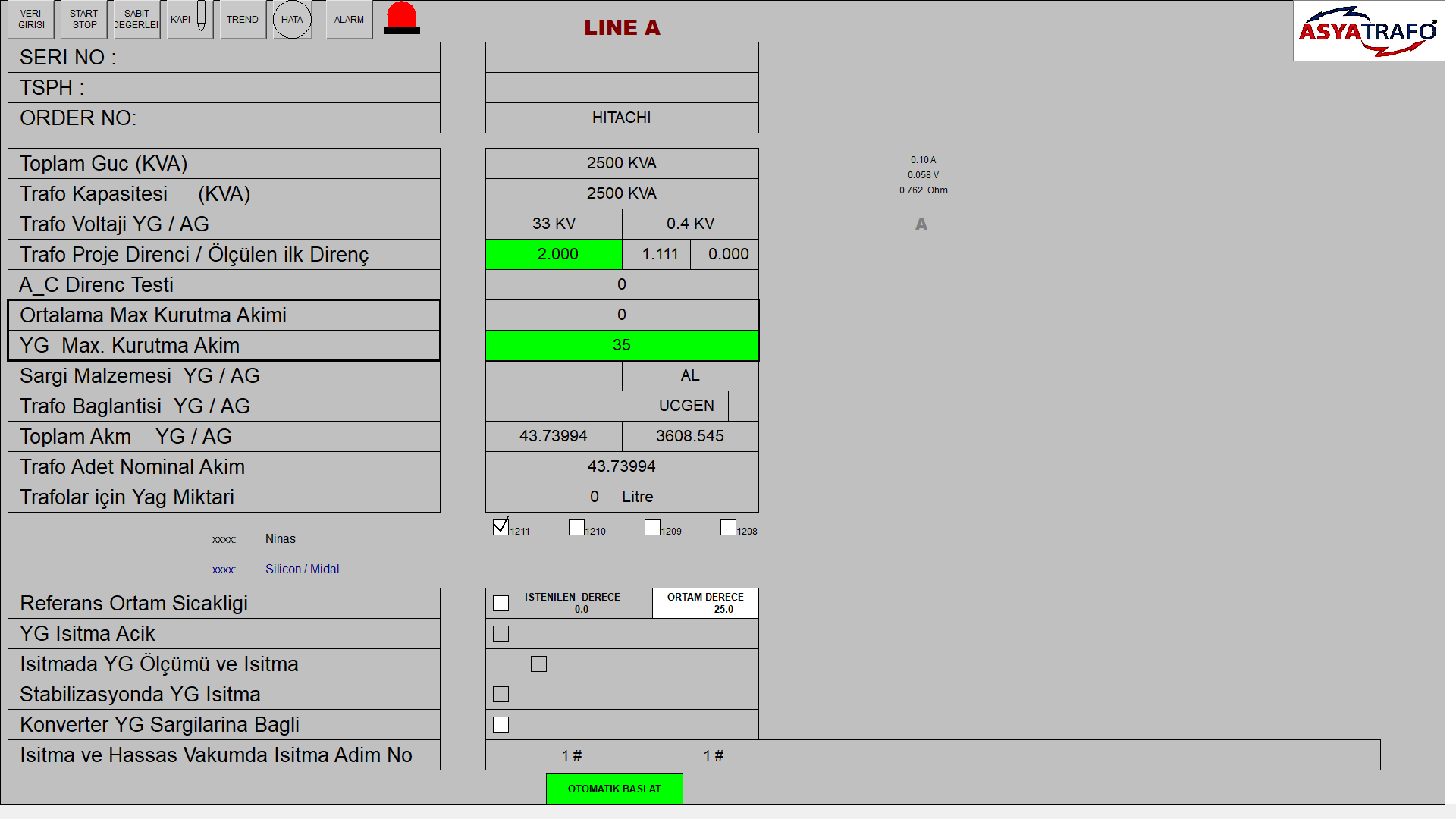

Project Name

Customer

Product Range

Capacity

Status

Hitachi Dudullu DTR

MDT LFH System Upgrade

6.3 kV to 120 kV

3×205 A

DONE

Hitachi Dudullu DTR

LDT LFH + Hot Air Drying System

6.3 kV to 155 kV

1×1000 A

DONE

Hitachi Dudullu DTR

LMDT LFH + Hot Air Drying System

6.3 kV to 45 kV

1×400 A

DONE

Hitachi Dudullu DTR

LDT LFH + Hot Air Drying System

6.3 kV to 85 kV

1×600 A

DONE

Hitachi Dudullu DTR

LMDT LFH Drying System

6.3 kV to 85 kV

1×300 A

DONE

ELTAŞ Transformer

LFH Drying System

6.3 kV to 85 kV

3×300 A

ONGOING

ELTAŞ Transformer

LFH Drying System

6.3 kV to 85 kV

2×300 A

DONE

ELTAŞ Transformer

LFH Drying System

6.3 kV to 85 kV

2×206 A

DONE

ELTAŞ Transformer

LFH Drying System

6.3 kV to 85 kV

2×206 A

DONE