Description

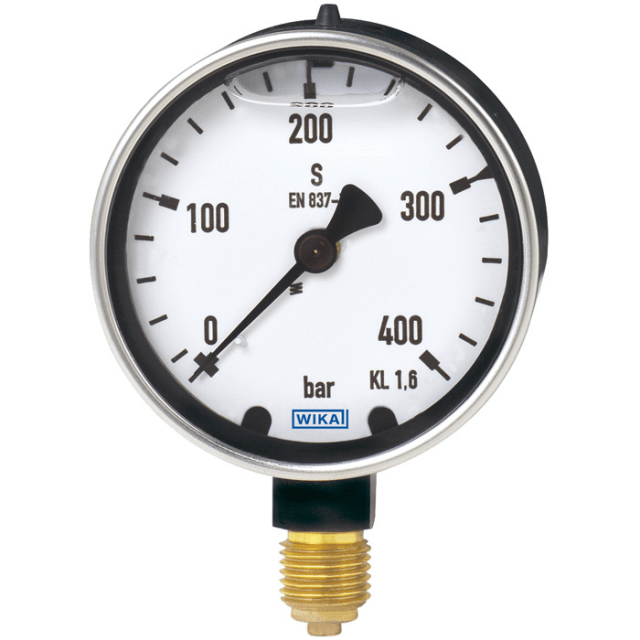

Wherever the process pressure has to be indicated locally and, at the same time, a signal transmission to the central control or remote centre is desired, the model PGT43HP intelliGAUGE® (patent, property right: e.g. DE 202007019025) can be used. Due to the metallic pressure element limit stop, these instruments have a high overload safety in the ranges of 40, 100 and 400 bar. The intelliGAUGE® model PGT43HP fulfils all safety-related requirements of the relevant standards and regulations for the on-site display of the working pressure of pressure vessels. An additional measuring point for mechanical pressure display can thus be saved. The model PGT43HP is based upon a model 432.36 high-quality, stainless steel safety pressure gauge with a nominal size of 100 or 160. The pressure measuring instrument is manufactured in accordance with EN 837-3.

The robust diaphragm measuring system produces a pointer rotation proportional to the pressure. An electronic angle encoder, proven in safety-critical automotive applications, determines the position of the pointer shaft – it is a non-contact sensor and therefore completely free from wear and friction. From this, the electrical output signal proportional to the pressure, e.g. 4 … 20 mA, is produced. The measuring span (electrical output signal) is adjusted automatically along with the mechanical display, i.e. the scale over the full display range corresponds to 4 … 20 mA. The electrical zero point can also be set manually. The electronic WIKA sensor, integrated into the high-quality pressure gauge, combines the advantages of electrical signal transmission with a local mechanical display that remains readable during a power failure.

An additional measuring point for mechanical pressure display can thus be saved.