Description

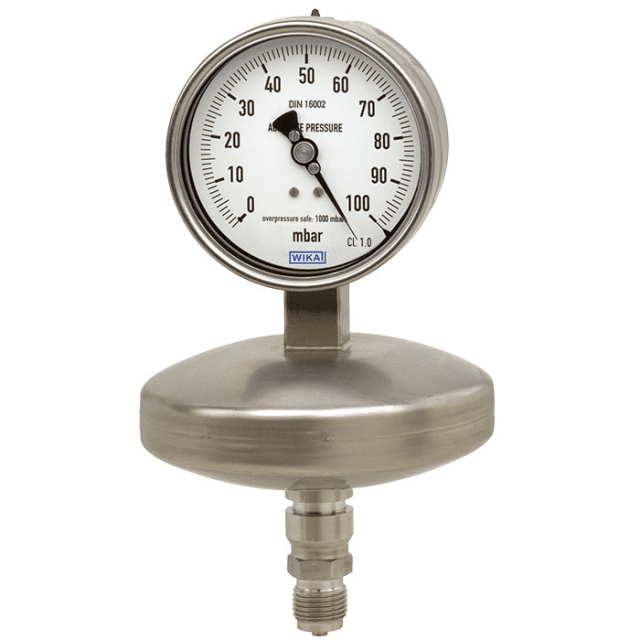

Diaphragm seal systems are used to protect the pressure measuring instrument from aggressive, adhesive, crystallising, corrosive, highly viscous, environmentally hazardous or toxic media. The diaphragm made of stainless steel provides for the separation from the medium. The pressure is transmitted to the measuring instrument via the system fill fluid which is inside the Diaphragm seal system.

The DSS22P complies with all requirements of the pharmaceutical industry. The particular suitability for pharmaceutical products rests on the fact that the measuring point can be cleaned while installed.

The requirements of CIP (cleaning in place) and SIP (sterilisation in place) are fulfilled.

The clamp connection enables the quick and easy dismounting and thus a simple cleaning with seal replacement.

The proven, all-welded construction ensures a long service life and permanent sealing.

The zero point can be set directly on the window using a hexagon wrench key without having to dismount the instrument.