Description

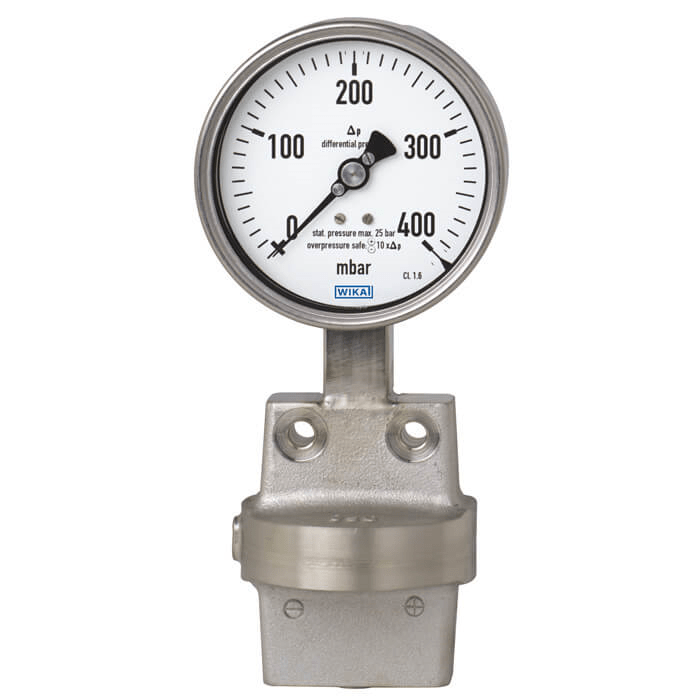

Diaphragm seals are used to protect the pressure measuring instrument from aggressive, adhesive, crystallising, corrosive, highly viscous, environmentally hazardous or toxic media. A diaphragm made of the appropriate material provides for the separation from the medium to be measured. Thus even the most difficult measuring requirements can be met by combining measuring instruments with diaphragm seals. A fluid inside the system, which can be chosen to suit the particular application, hydraulically transmits the pressure to the measuring instrument. Almost limitless application possibilities exist due to the large number of available variants, such as diaphragm seal designs or materials. The type of process connection (flange, threaded and sterile connection) and the basic method of manufacture are important design differentiation criteria. For further technical information on diaphragm seals and diaphragm seal systems see IN 00.06 “Application, operating principle, designs”. The model L981.22 in-line diaphragm seals with clamp connections, due to their circular design, can be mounted directly into the pipeline, meaning no special measuring point connection is required. Through the integration into the process line, turbulences, dead spaces, corners and other obstructions can be avoided. For this diaphragm seal WIKA uses a completely round diaphragm, which, due to the unobstructed flow of the media, produces an automatic cleaning of the chamber.

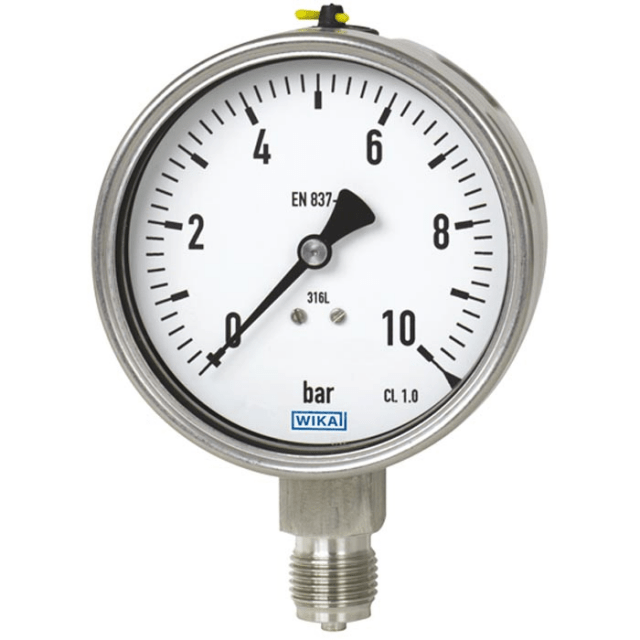

The diaphragm seal systems can withstand the cleaning vapour temperatures occurring in the SIP processes and thus ensure a sterile connection between the medium to be measured and the diaphragm seal. Assembly of the diaphragm seal and measuring instrument is made via a direct assembly as standard or optionally via a cooling element or a flexible capillary. For the material selection WIKA offers a variety of solutions, in which the upper housing and the diaphragm are made of identical materials. Stainless steel 316L (1.4435) is used as standard material, other special materials are available on request. Measuring systems with model L981.22 WIKA diaphragm seals are successfully used in the life science industry, in food production, pharmaceutical and biotechnology applications.