Description

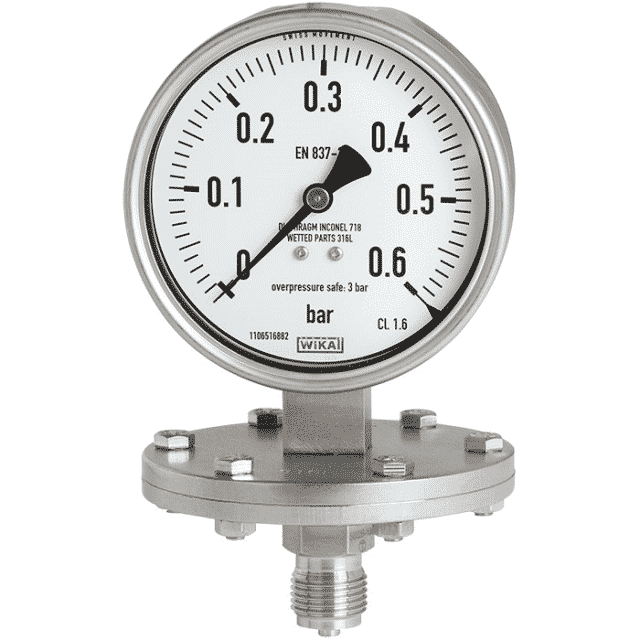

The differential pressure gauges of the DELTA-line product family are primarily used for the monitoring and control of low differential pressures where there are high requirements in terms of one-sided overload and static pressure.

Typical markets for the model DPGS40TA are the shipbuilding industry, process heating technology, the heating, ventilation and air-conditioning industries, the water/wastewater industry, and machine building and plant construction.

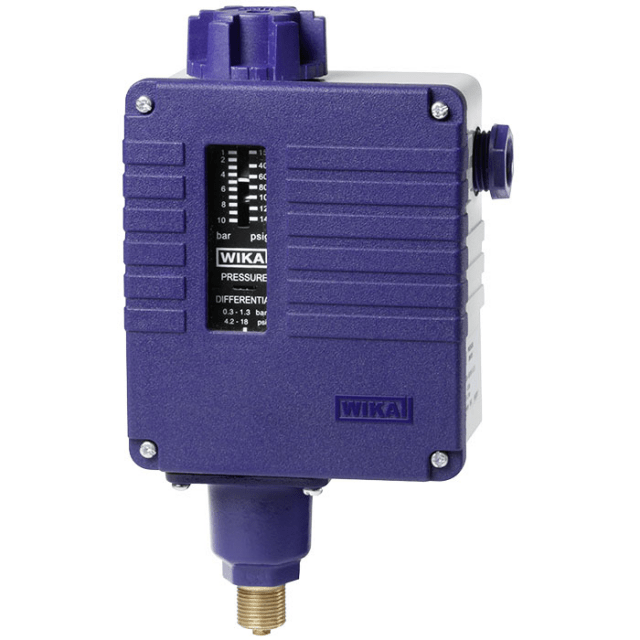

Wherever a differential pressure has to be indicated locally and, at the same time, circuits need to be switched safely dependent on a defined differential pressure, the DELTA-comb finds its use.

The differential pressure remains readable on the mechanical display, even if the voltage supply is lost.

The switch point is accessible from the front and can be set in the range of 10 … 100 % of the end value of the measuring range by means of an assistant scale.

As a result of the low measuring range of 0 … 250 mbar, the instrument can also be used for applications with low differential pressures.

The measuring chamber, depending on the requirement and application, can be made from aluminium or stainless steel. Through the increased stability, the stainless steel measuring chamber is also suitable for gaseous media.

The special feature of the DELTA-comb with component testing is shown by the variety of approvals and certificates. These ensure the suitability for operation in the respective application.