Description

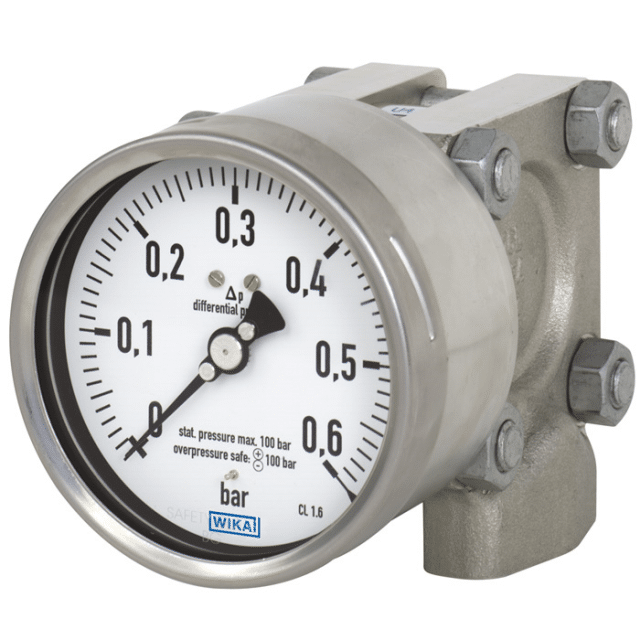

The differential pressure gauges of the DELTA-line product family are primarily used for the monitoring of low differential pressures where there are high requirements in terms of one-sided overload and static pressure.

Typical markets for these products are the shipbuilding industry, process heating technology, the heating, ventilation and air-conditioning industries, the water/wastewater industry, and machine building and plant construction. For these, the main function of the measuring instruments is the monitoring of filters, compressors and pumps.

Often in these applications, alongside the indication of the differential pressure, the current working pressure is also relevant. A version with integrated working pressure indication is therefore available for the model DPG40. The two easily readable, mechanical on-site displays enable the simultaneous reading of the working and the differential pressure.

Furthermore, this saves on an additional measuring and sealing point, reducing additional expense for piping and mounting.

As a result of the low scale range of 0 … 160 mbar, the instrument can also be used for applications with low differential pressures. A further key feature is the high accuracy of down to 1.6 % which is important for most applications.

The measuring chamber, depending on the requirement and application, can be made from aluminium or stainless steel. Through the increased stability, the stainless steel measuring chamber is also suitable for gaseous media.