Description

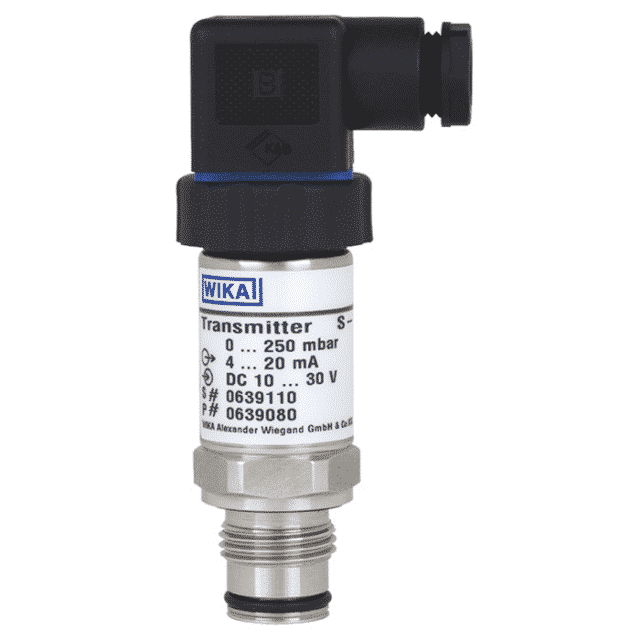

In the process industry, differential pressure measurement using primary and secondary circuits has several advantages over conventional differential pressure methods. The measuring locations, which are usually several metres apart, are connected via a flexible and easily routed cable.

This eliminates the need for capillaries, which are complex to install and susceptible to temperature changes.

Flexible configuration

Two identical or two different instruments can be combined. The prerequisite is that one of the instruments is used as the primary instrument.

This processes the measured values supplied by both individual instruments. An internal calculation determines the pressure difference and relays it to the controller via the current loop or the bus system. The secondary instrument only supplies the measured values to the primary instrument via a bus line.

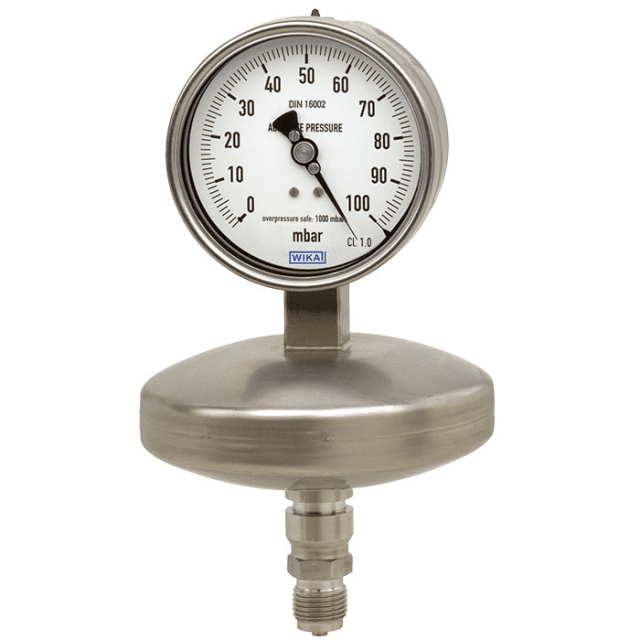

The possibilities for combination and the flexible connection often enable a configuration in which diaphragm seals are no longer needed for process separation. For example, a flush system can be used at the bottom of the vessel, while an open process connection in the upper part of the tank poses no problem for measurement in the superimposed gas.

Insensitive to temperature fluctuations

Especially with vessels that are often outdoors, it is problematic when the sun shines on the capillaries. An increase in pressure due to the effects of temperature often falsifies the measuring result.

The cable used for electronic differential pressure measurement has almost no influence on the measuring result when heated.