Description

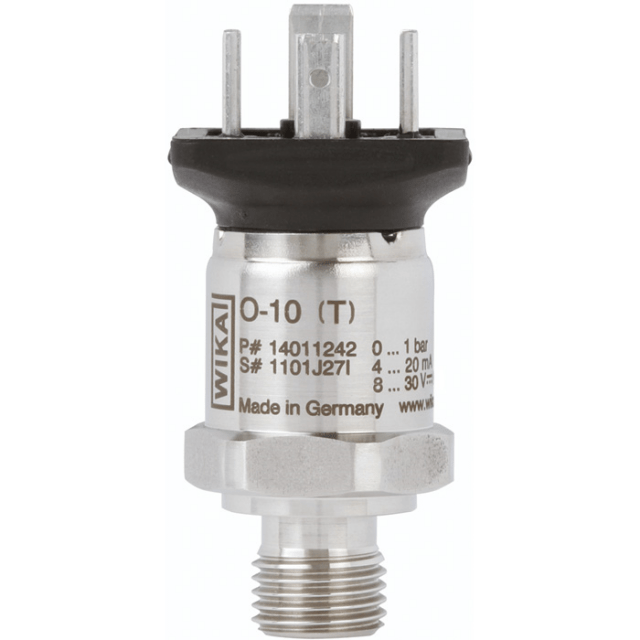

The model DPT-20, with its 4 … 20 mA, 4 … 20 mA HART®, FOUNDATION™ Fieldbus or PROFIBUS® PA output signals, combined with the intrinsic safety or flameproof enclosure ignition protection type, is ideally suited for application in appropriate systems. The development of the transmitter in accordance with the demands of SIL (Safety Integrated Level) IEC 61508 also makes it applicable for plants with special safety requirements.

Versatile in application

The model DTP-20 is suitable for many industrial measuring requirements, such as flow measurement using differential pressure transducers, level measurement in open or closed tanks or filter and pump monitoring. With mounted diaphragm seals, the model DTP-20 is also suitable for harsh process conditions. As a result of the available measuring ranges from -10 … +10 mbar to -16 … +16 bar [-0.15 … +0.15 psi to -240 … +240 psi] and a static pressure limitation of up to 400 bar [5,800 psi], the instrument can be used in almost any application. The internal digital signal processing, combined with proven sensors, guarantees high accuracy and the best long-term stability.

There are seven different case versions available, and thus it is possible to select a variant suited to every operating environment. The case itself can be rotated through 330° and is available in plastic, aluminium and stainless steel.

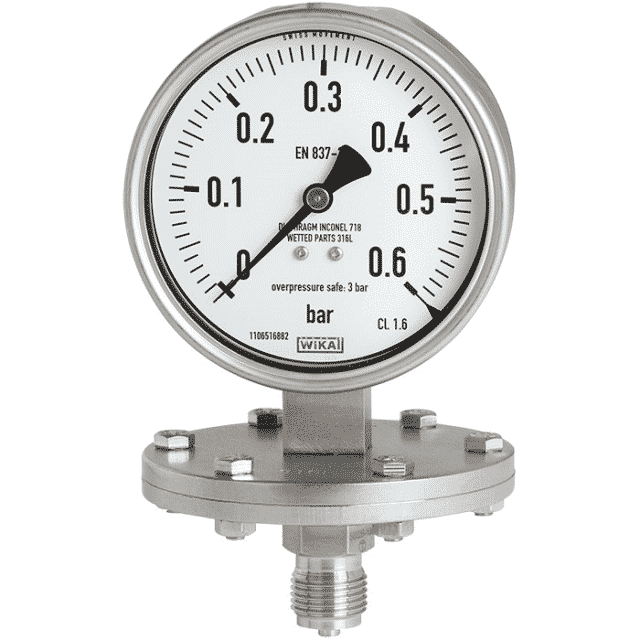

An electropolished stainless steel case (316L) is available to meet the high demands of the food and pharmaceutical industries.

Easy configuration and operation

Service and configuration at the instrument is carried out using the optional display and operating module, which can be fitted in four positions. The operating menu has a simple and self-explanatory structure and has many selectable languages. Alternatively, the operating parameters can be set using the PACTware™ free and non-proprietary configuration software. An instrument-specific DTM enables easy integration into corresponding process control systems.